Table of Contents

Unleashing Strength with the Strong Power Petrol Engine

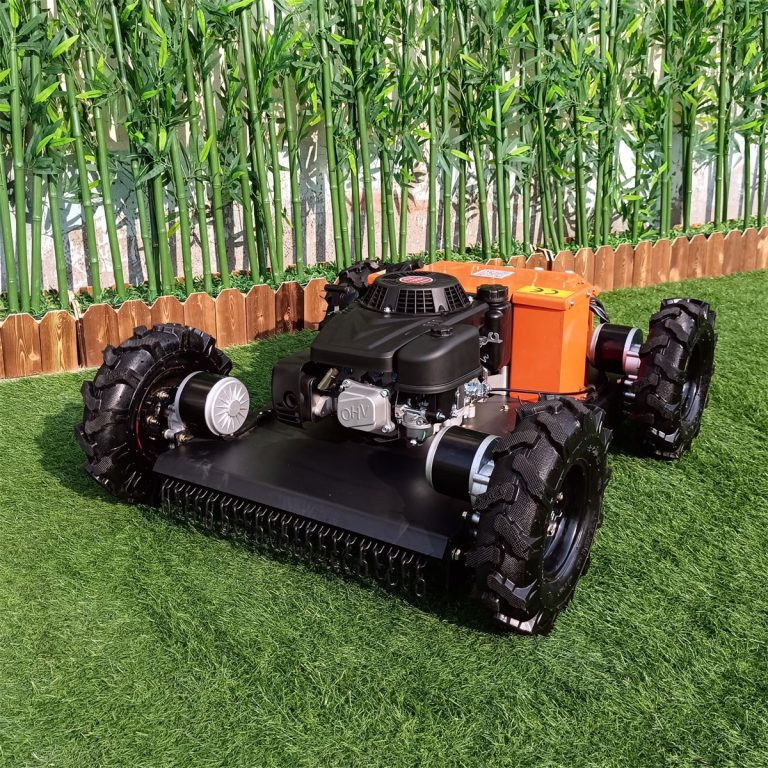

The strong power petrol engine time-saving and labor-saving crawler cordless hammer mulcher is a game changer in the world of landscaping and maintenance. This innovative machine is powered by a robust V-type twin-cylinder gasoline engine, specifically the Loncin brand, model LC2V80FD. With a rated power of 18 kW at 3600 rpm and a displacement of 764cc, this engine delivers exceptional performance to tackle even the toughest tasks. One of the standout features of this powerful engine is its clutch mechanism, which engages only when it reaches a predetermined rotation speed. This ensures that the machine operates efficiently, maximizing both power and fuel economy while minimizing wear and tear. The intelligent design allows for seamless operation in various environments, making it an essential tool for professionals in landscaping and agricultural sectors. Additionally, the high reduction ratio provided by the worm gear reducer multiplies the already impressive torque generated by the servo motor. This results in immense output torque, making uphill climbs easier than ever. The self-locking function ensures safety during operation, preventing unintended movements when the throttle is not engaged. This combination of power and safety is crucial for maintaining productivity on steep terrains.

Versatile and Efficient: The Crawler Cordless Hammer Mulcher

The strong power petrol engine time-saving and labor-saving crawler cordless hammer mulcher stands out for its versatility. Designed for multi-functional use, it features interchangeable front attachments, allowing users to switch between a 1000mm-wide flail mower, hammer flail, forest mulcher, angle snow plow, or snow brush with ease. This adaptability makes it perfect for various tasks, from heavy-duty grass cutting to vegetation management and snow removal.

The strong power petrol engine time-saving and labor-saving crawler cordless hammer mulcher stands out for its versatility. Designed for multi-functional use, it features interchangeable front attachments, allowing users to switch between a 1000mm-wide flail mower, hammer flail, forest mulcher, angle snow plow, or snow brush with ease. This adaptability makes it perfect for various tasks, from heavy-duty grass cutting to vegetation management and snow removal.

The machine’s electric hydraulic push rods enable remote height adjustment of attachments, providing users with added convenience and efficiency. This feature is particularly beneficial for operators working in diverse landscapes, where varying heights and conditions may require quick adjustments to maintain optimal performance.

The machine’s electric hydraulic push rods enable remote height adjustment of attachments, providing users with added convenience and efficiency. This feature is particularly beneficial for operators working in diverse landscapes, where varying heights and conditions may require quick adjustments to maintain optimal performance.

Furthermore, the intelligent servo controller regulates the motor speed and synchronizes the left and right tracks. This results in smooth and straight-line travel without the need for constant adjustments, significantly reducing the operator’s workload. Enhanced stability during operation minimizes risks associated with over-correction, especially on slopes, ensuring a safer working environment.

Furthermore, the intelligent servo controller regulates the motor speed and synchronizes the left and right tracks. This results in smooth and straight-line travel without the need for constant adjustments, significantly reducing the operator’s workload. Enhanced stability during operation minimizes risks associated with over-correction, especially on slopes, ensuring a safer working environment.