Table of Contents

Features of the Dual-Cylinder Four-Stroke 100cm Cutting Blade Compact Remote Flail Mulcher

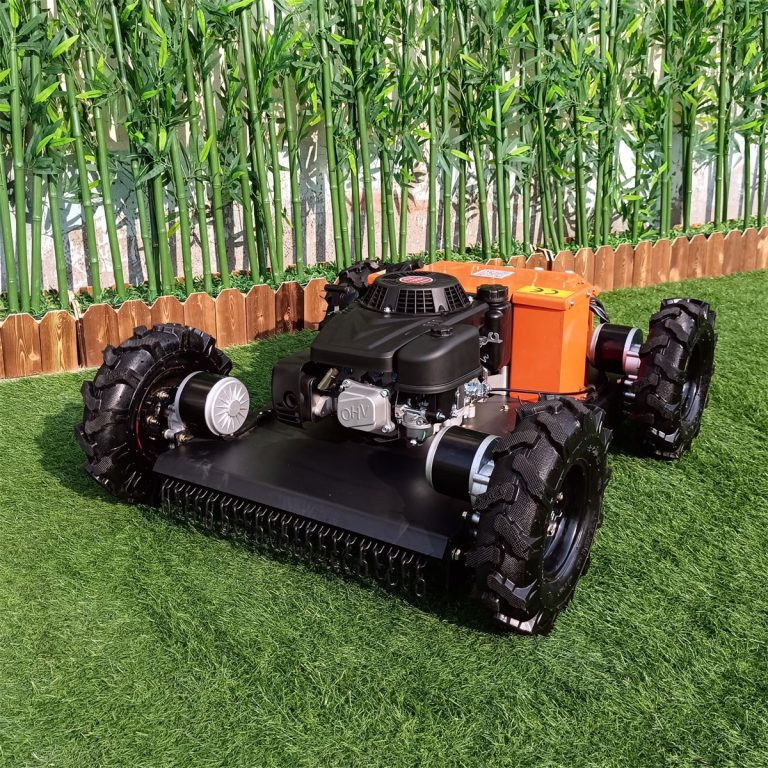

The dual-cylinder four-stroke 100cm cutting blade compact remote flail mulcher is engineered for exceptional performance, making it a reliable choice for various landscaping needs. At its core, this machine is powered by a V-type twin-cylinder gasoline engine from Loncin, model LC2V80FD. With a rated power of 18 kW at 3600 rpm and a robust 764cc capacity, it delivers impressive output that ensures efficient operation. This advanced engine features a clutch system that engages only at a predetermined rotational speed, maximizing efficiency while protecting the machine from unnecessary wear. Such thoughtful engineering translates to longer life and reduced maintenance costs, making it an ideal investment for both commercial and residential users.

This advanced engine features a clutch system that engages only at a predetermined rotational speed, maximizing efficiency while protecting the machine from unnecessary wear. Such thoughtful engineering translates to longer life and reduced maintenance costs, making it an ideal investment for both commercial and residential users.

Additionally, the dual-cylinder design enhances torque delivery for challenging tasks, including climbing slopes and managing dense vegetation. This makes the mulcher suitable for a range of environments, from overgrown fields to sloped terrains.

Additionally, the dual-cylinder design enhances torque delivery for challenging tasks, including climbing slopes and managing dense vegetation. This makes the mulcher suitable for a range of environments, from overgrown fields to sloped terrains.

Thanks to its compact design, the dual-cylinder four-stroke 100cm cutting blade compact remote flail mulcher is easy to maneuver, allowing operators to navigate tight spaces with ease. Its versatility is further enhanced by the ability to attach various implements, making it an all-in-one solution for multiple landscaping jobs.

Thanks to its compact design, the dual-cylinder four-stroke 100cm cutting blade compact remote flail mulcher is easy to maneuver, allowing operators to navigate tight spaces with ease. Its versatility is further enhanced by the ability to attach various implements, making it an all-in-one solution for multiple landscaping jobs.

Advanced Safety and Efficiency Features

Safety is paramount in the design of the dual-cylinder four-stroke 100cm cutting blade compact remote flail mulcher. It is equipped with a built-in self-locking function, ensuring that the machine only moves when both power is on and throttle is applied. This feature effectively prevents unintended sliding, significantly enhancing operational safety for the user.

The intelligent servo controller plays a crucial role in maintaining stability and performance. It precisely regulates motor speed and synchronizes the left and right tracks, allowing the mower to travel in a straight line without constant adjustments. This reduces the operator’s workload and minimizes risks associated with overcorrection, especially on steep slopes.

Moreover, the high reduction ratio of the worm gear reducer multiplies the torque from the powerful servo motors, providing immense output torque for climbing resistance. In case of power loss, the mechanical self-locking feature ensures that the machine does not slide down hills, thus safeguarding both the equipment and the operator.

Safety is paramount in the design of the dual-cylinder four-stroke 100cm cutting blade compact remote flail mulcher. It is equipped with a built-in self-locking function, ensuring that the machine only moves when both power is on and throttle is applied. This feature effectively prevents unintended sliding, significantly enhancing operational safety for the user.

The intelligent servo controller plays a crucial role in maintaining stability and performance. It precisely regulates motor speed and synchronizes the left and right tracks, allowing the mower to travel in a straight line without constant adjustments. This reduces the operator’s workload and minimizes risks associated with overcorrection, especially on steep slopes.

Moreover, the high reduction ratio of the worm gear reducer multiplies the torque from the powerful servo motors, providing immense output torque for climbing resistance. In case of power loss, the mechanical self-locking feature ensures that the machine does not slide down hills, thus safeguarding both the equipment and the operator.